Single Phase Motors

are capable of functioning for longer hours without any obstruction. These single phase motors that we have are known for their compact construction that makes them ideal being used in various material handling equipment.

STAR-DELTA AIR BREAK CONTOL PANEL FOR THREE PHASE SUBMERSIBLE PUMP – MCPABSD

STAR-DELTA AIR BREAK CONTOL PANEL FOR THREE PHASE

SUBMERSIBLE PUMP – MCPABSD

HAVING 2 PUSH BUTTONS With Automatic Motor Starter Control Switch Cum Single Phase Preventer

Code No. H.P

394 15&20

395 25&30

396 35&40

397 45&50

398 60

STAR-DELTA AIR BREAK CONTOL PANEL FOR THREE PHASE SUBMERSIBLE PUMP HAVING 3 PUSH BUTTONS-MCPABSD

STAR-DELTA AIR BREAK CONTOL PANEL FOR THREE PHASE SUBMERSIBLE PUMP HAVING 3 PUSH BUTTONS-MCPABSD

With Automatic Motor Starter Control Switch Cum Single Phase Preventer

Submersible pumps

Submersible pumps are a type of water pump that are designed to be fully submerged in water, typically in a well, borehole, or other water source. They are used to pump water to the surface for a variety of applications, such as irrigation, water supply, and dewatering.

Submersible pumps are made up of two main components: the motor and the pump. The motor is hermetically sealed and designed to operate underwater, while the pump is located at the bottom of the well or borehole and is used to draw water up to the surface.

One of the advantages of submersible pumps is their efficiency. Because they are located near the source of the water, they do not need to overcome the pressure of gravity and can operate more efficiently than surface pumps. They are also relatively quiet and require less maintenance than other types of pumps.

Submersible pumps are available in a variety of sizes and capacities, ranging from small units for domestic use to large units for industrial and agricultural applications. They can be powered by electricity or diesel, depending on the specific application.

When selecting a submersible pump, it is important to consider factors such as the required flow rate, the lift height, and the type of fluid being pumped. It is also important to choose a pump that is properly sized for the application, as an undersized pump may not be able to meet the required flow rate, while an oversized pump may consume more energy than necessary

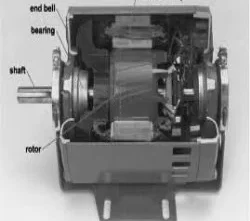

Three phase induction motors

Three phase induction motors are a type of electric motor that are commonly used in industrial and commercial applications. They are more efficient and powerful than single phase induction motors, and are able to handle heavy loads and high speeds.

Three phase induction motors have three windings that are connected to a three-phase power source. The windings are spaced 120 degrees apart, which creates a rotating magnetic field in the stator. The rotating magnetic field interacts with the magnetic field of the rotor to produce torque and rotation.

There are two types of three phase induction motors: squirrel cage and wound rotor motors. Squirrel cage motors have a rotor with conductive bars that are shorted together at both ends, forming a “cage” or “squirrel cage” shape. When the stator creates a rotating magnetic field, eddy currents are induced in the conductive bars, which creates a magnetic field that interacts with the stator field and produces torque.

Wound rotor motors have a rotor with windings that are connected to slip rings. The slip rings are connected to external resistors, which allow the resistance of the rotor circuit to be varied. When the motor is started, the resistors are set to a high value, which creates a high starting torque. As the motor reaches full speed, the resistors are gradually reduced, which increases the efficiency of the motor.

Three phase induction motors are widely used in a variety of industrial applications, such as pumps, compressors, conveyors, and machines tools. They are efficient, reliable, and can operate at high speeds and under heavy loads.

Lighting Equipment Company

Lighting Equipment Company