MINI D.O.L. AIR BREAK CONTROL PANEL FOR THREE PHASE MOTOR & SUBMERSIBLE PUMP-MMCPTMAS

MINI D.O.L. AIR BREAK CONTROL PANEL FOR THREE PHASE MOTOR & SUBMERSIBLE PUMP-MMCPTMAS

With Automatic Motor Starter Control Switch Cum Single Phase Preventer Digital Electronic Combined V+A Meter

REWIRABLE SWITCH FUSE COMBINATION UNIT SPN / DP- MSE

REWIRABLE SWITCH FUSE COMBINATION UNIT SPN / DP MODEL – MSE

Rated Amp. Rated Volts

16 SPN 240V

16 DP 240V

32 SPN 240V

32 DP 240V

32 DP 415V

63 DP 415V

100 DP 415V

16 DP 240V

REWIRABLE SWITCH FUSE COMBINATION UNIT TP/TPN – MSE

REWIRABLE SWITCH FUSE COMBINATION UNIT TP/TPN – MSE

Code No. Rated Amp. Rated Volts

511 16 TP 415V

512 16TPN 415V

513 32 TP 415V

514 32 TPN 415V

515 63 TP 415V

516 63 TPN 415V

517 100 TP 415V

518 100 TPN 415V

519 200 TP 415V

520 200 TPN 415V

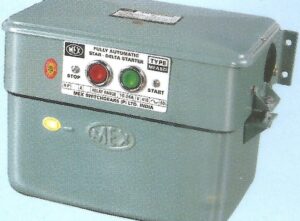

SEMI AUTOMATIC STAR-DELTA OIL IMMERSED STARTER Having Three Push Buttons with Bimetal Thermal Relay-MSASD

SEMI AUTOMATIC STAR-DELTA OIL IMMERSED STARTER Having Three Push Buttons with Bimetal Thermal Relay-MSASD

SEMI AUTOMATIC STAR-DELTA OIL IMMERSED STARTER

Having Three Push Buttons with Bimetal Thermal Relay-MSASD

SEMI AUTOMATIC STAR-DELTA OIL IMMERSED STARTER with Bimetal Thermal Relay (Heavy Duty Contacts) – SUPER MEX

SEMI AUTOMATIC STAR-DELTA

OIL IMMERSED STARTER

with Bimetal Thermal Relay (Heavy Duty Contacts) – SUPER MEX

STAR-DELTA AIR BREAK CONTOL PANEL FOR THREE PHASE SUBMERSIBLE PUMP – MCPABSD

STAR-DELTA AIR BREAK CONTOL PANEL FOR THREE PHASE

SUBMERSIBLE PUMP – MCPABSD

HAVING 2 PUSH BUTTONS With Automatic Motor Starter Control Switch Cum Single Phase Preventer

Code No. H.P

394 15&20

395 25&30

396 35&40

397 45&50

398 60

STAR-DELTA AIR BREAK CONTOL PANEL FOR THREE PHASE SUBMERSIBLE PUMP HAVING 3 PUSH BUTTONS-MCPABSD

STAR-DELTA AIR BREAK CONTOL PANEL FOR THREE PHASE SUBMERSIBLE PUMP HAVING 3 PUSH BUTTONS-MCPABSD

With Automatic Motor Starter Control Switch Cum Single Phase Preventer

Lighting Equipment Company

Lighting Equipment Company